O-rings norelem FR

By A Mystery Man Writer

O-rings are universal sealing elements used to seal against liquid or gaseous median. They are suitable for static and minor dynamic applications. O-rings can be used for radial and axial sealing. The sealing occurs during installation by the radial or axial compression of the cross-section. During operation, the median pressure increases the deformation of the O-ring and so increases the sealing effectiveness. For best sealing effectiveness, the O-ring should have the largest possible cross-section. During installation the correct groove size, compaction, elongation/compression should be ensured. By static use the compaction should be 15 - 30% of the cross-section. By dynamic use it should be 10 - 18% (hydraulic), 4 - 12% (pneumatic). With regard to the ID, when installed the O-ring should be stretched max 6% compressed max 3% The material NBR has a high wear resistance and is resistant to mineral oil based lubricating oils and grease, hydraulic oils (H, H-L, H-LP), high-flashpoint pressure fluids (HFA, HFB, HFC), aliphatic hydrocarbons, silicon oil and grease, water up to ca. 80° C

Anel Oring em FPM Viton 2120 - Diam.Int.25,07mm x Secção 2,62mm

ENCAPSULATED O-RINGS - NimaxSeals - FEP/PFA FKM CORE

Game Ready O-Rings, Hose Connector Replacement (10 Rings per pack)

Stainless steel ball transfer unit - 95153 - norelem - Éléments

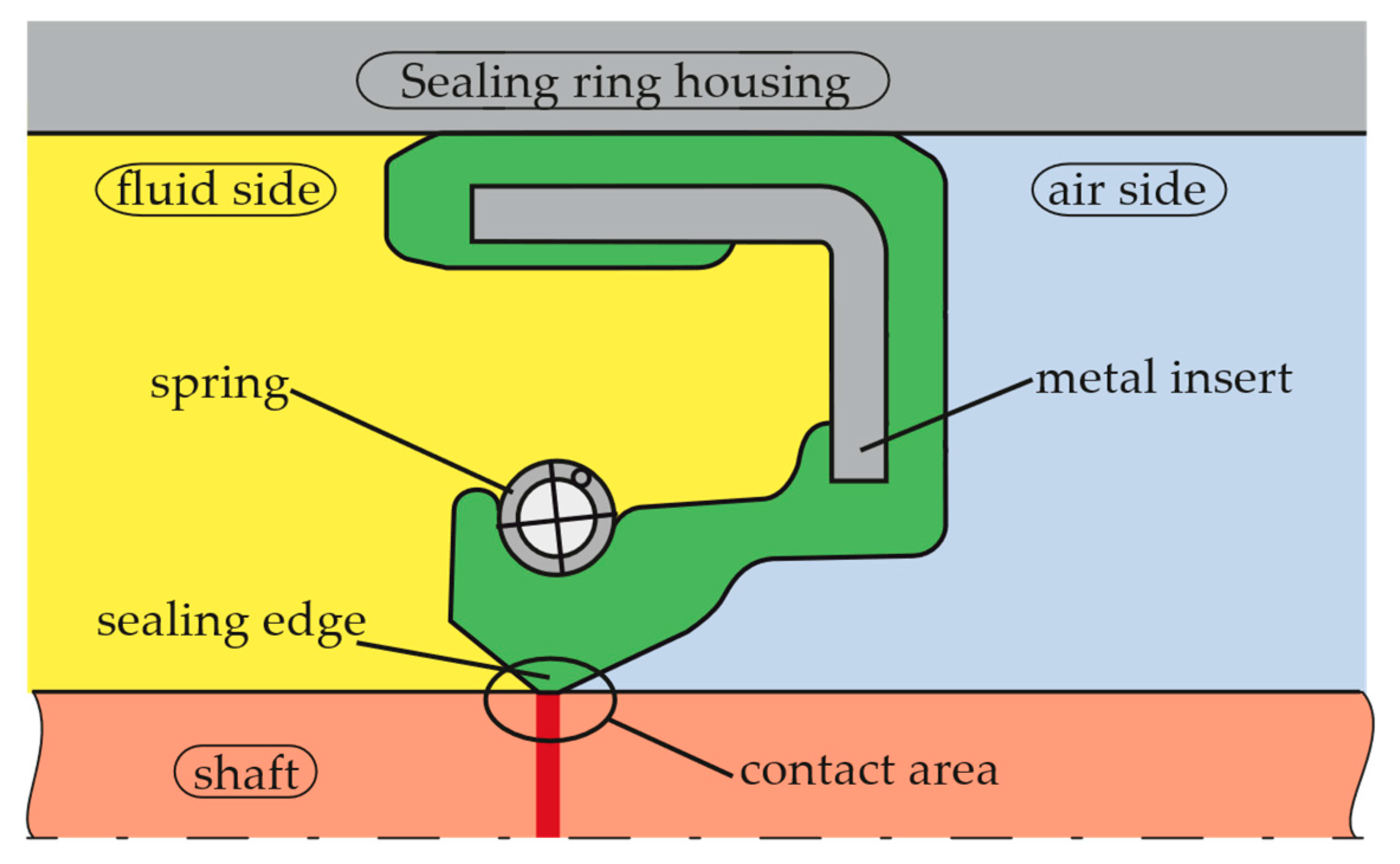

Applied Sciences, Free Full-Text

Hoist rings

Nbr O-ring D1= 30 D2= 3.5 Ral 3003 A= 350 D= M08 Ref. Norelem 23900

Self-aligning pads with O-ring and exchangeable inserts

Threaded insert - 07652 - norelem - Éléments standard mécaniques

KIPP LinkedIn

Boss, Face, and Flange O-Rings

Self-aligning pads, adjustable, with O-ring, Form F, flattened

- Thigh High Compression Stocking Footless - Pair, Thigh-Hi Leg Compression Sleeves Unisex, 20-30mmHg Gradient Compression with Silicone Band, Opaque

- NWT Old Navy Green Blue Plaid Flannel Pajama Pants Sleep Lounge Men SMLXL XXL

- Second Skin Invisible Thong – Sozy

- Buy Nike Running pants online

- Lululemon 'We Made Too Much' restock: Get deals on fan favorite