Tilt Up Lift Inserts

By A Mystery Man Writer

Consisting of a forged foot anchor, 4-leg wire base and plastic void former. The insert is positioned with the void direction toward the top of the panel and then is tied in place to the rebar cage. Lifting Hardware allows quick attachment to the insert and ground release after panel has been erected and braced.

Tilt-Up Wall Construction: Benefits of Using ICF

Dayton Superior - The T110 Superior Lift System requires fewer inserts, up to 70% less crane time and has lower installation and erection costs! #YourSolution #TiltUp #DaytonSuperior

How Are Tilt-Up Walls Constructed?

Tilt-Up Construction: The Process of Erecting a Tilt-Up Building Explained

Tilt Up Helical Ground Anchor (HGA) Bracket

The Tilt-Up Construction Process Explained - Tiltwall Ontario Inc.

Tilt-Up Concrete Construction - Intermountain Concrete Specialties

Tilt Up Lift Inserts

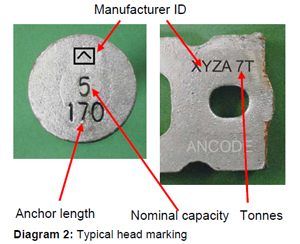

Lifting inserts for tilt-up and pre-cast concrete construction

World's Tallest Tilt-Up Panel Erected Near Miami, Florida : TILT-UP TODAY – A publication of the Tilt-Up Concrete Association (TCA)

STRUCTURE magazine Developing a Temporary Bracing Plan for Tilt-Up Panels

The Tilt-up Construction Process - Tilt Wall Ontario Inc.

Concrete Tilt Wall Panel Installation

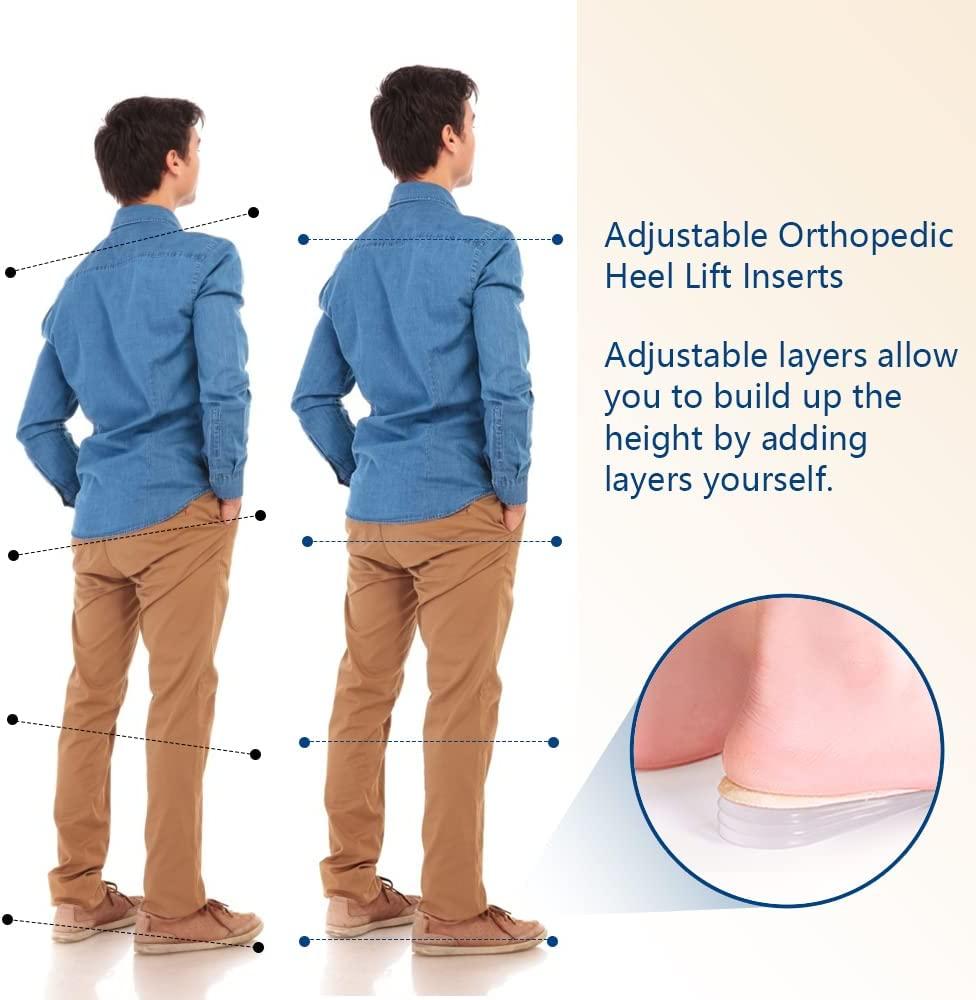

- Kimihome Adjustable Orthopedic Heel Lift Inserts, Upgrade and Widen Height Increase Insoles, 1/4 to 1 Gel Shoe Heels Inserts for Leg Length Discrepancies. (4 Layers,1 Pair)

- VersaLifts V2™ Heel Lift Inserts - Green

- VSG800A117KIT Rotary Lift Mount Demount Head Plastic Insert

- Rubber Heel Lifts for Sale Orthopedic Shoe Lift Inserts

- Vise Power Lift & Semi Inserts- 10 Pack