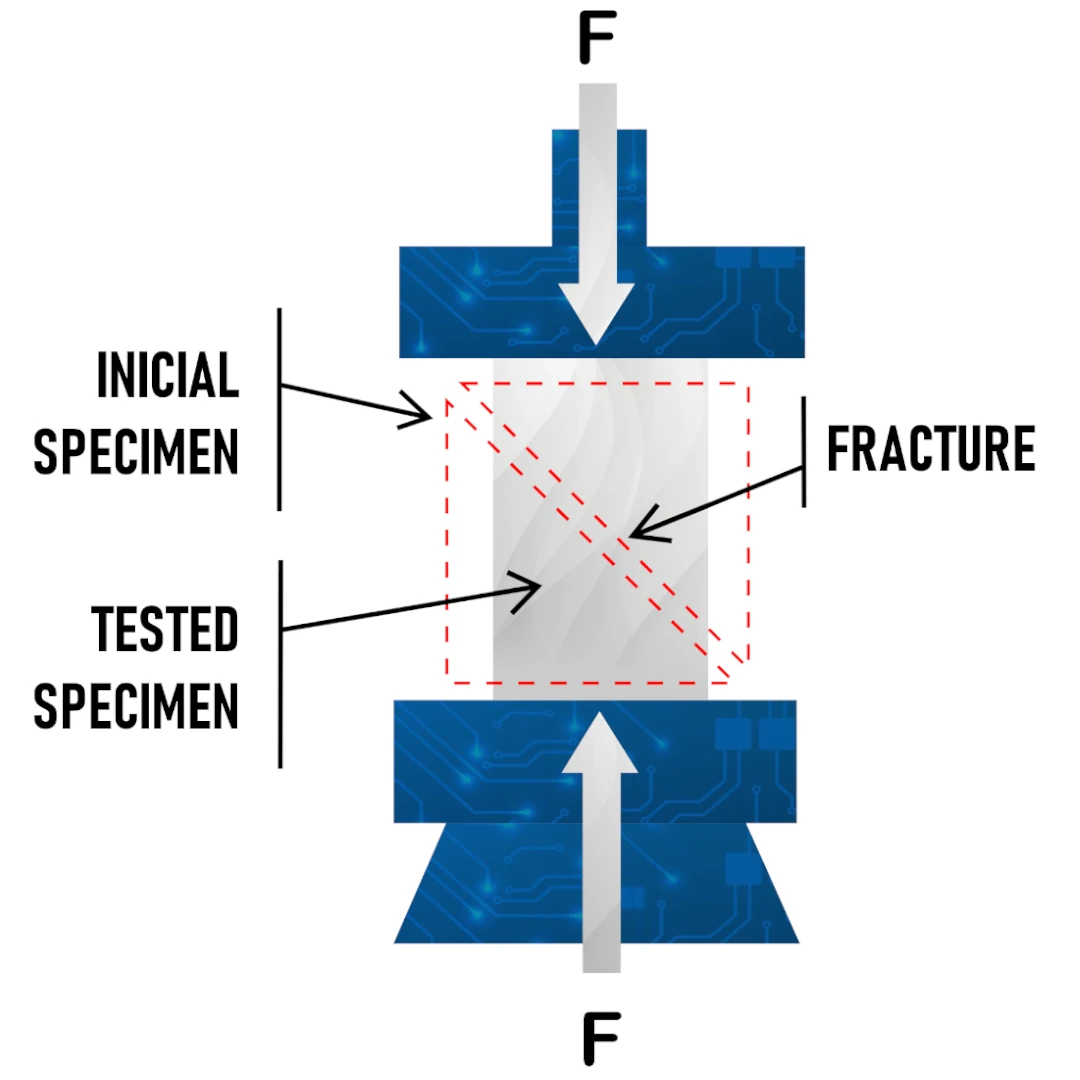

Aluminum foam specimen before and after the compression test

By A Mystery Man Writer

Download scientific diagram | Aluminum foam specimen before and after the compression test from publication: Influence of the Manufacturing Parameters on the Compressive Properties of Closed Cell Aluminum Foams | The important properties of metallic foams such as good energy absorption, recyclability, noise absorption, etc. have put them at the forefront of technological development over recent years, especially for fields where the weight is a major concern. The production however, | Foams, Foam and Recycling | ResearchGate, the professional network for scientists.

Tensile strength of foaming specimen: (a) Foam sample, (b) tensile

10.Nondestructive observation of compression behavior of pores in three-layered functionally graded aluminum foam of A1050/A6061/ADC12 by X-ray computed tomography

Mechanical behavior of aluminum foam/polyurethane interpenetrating phase composites under monotonic and cyclic compression - ScienceDirect

Muhammad Ali NAEEM, MSc. Mechanical Engineering

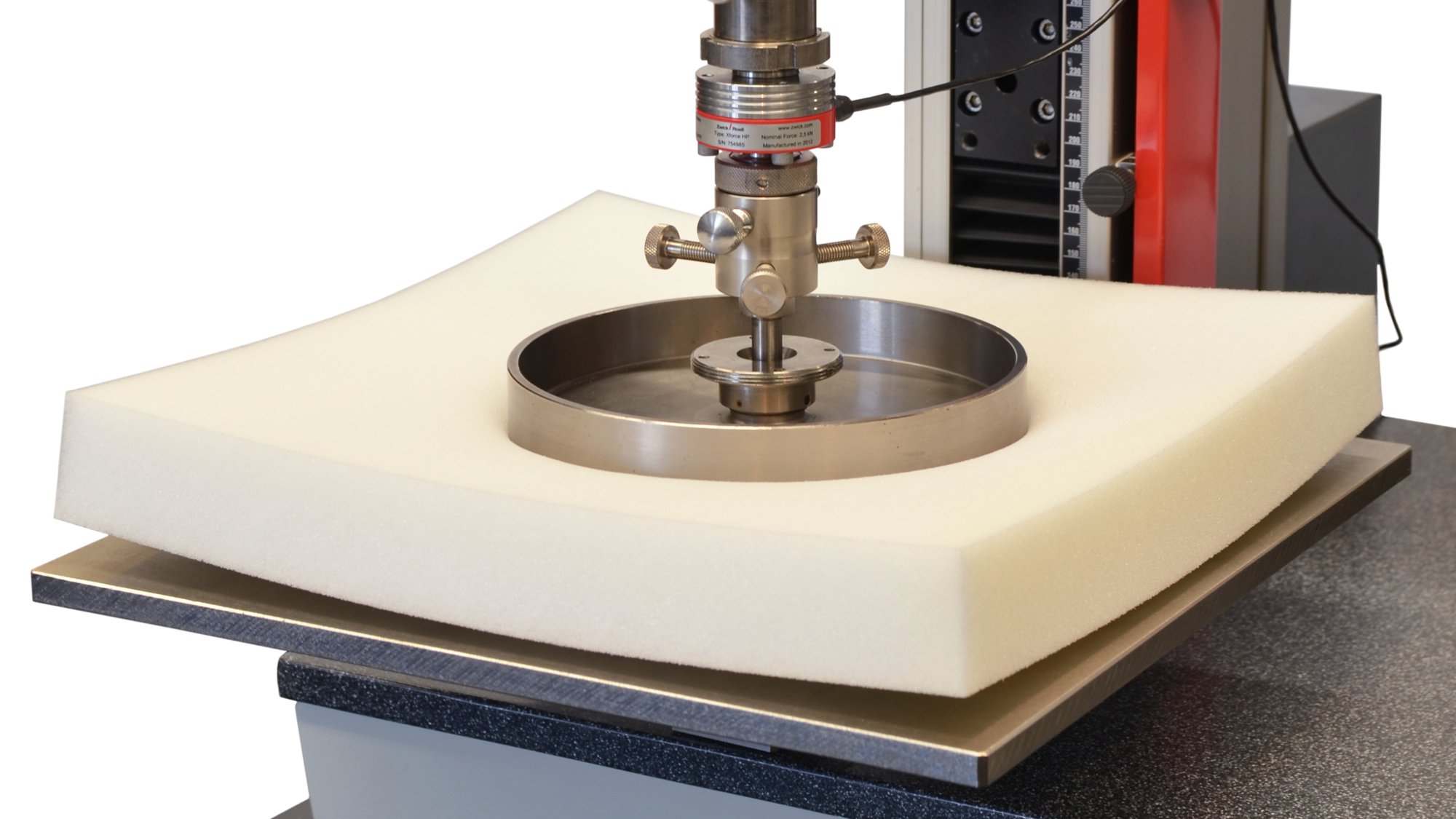

Compression Testing: Machine & Test, Strength & Tension

Compression of an Aluminum Foam

Compression Testing: Methods, Applications, and Benefits

Enhancement of quasi-static compression strength for aluminum closed cell foam blocks shielded by aluminum tubes

Applied Sciences, Free Full-Text

Preparation of specimens and quasi-static compression tests. (a) Four

Average porosity and compressive properties of aluminum foam specimens

Fabrication and compressive behaviour of an aluminium foam composite - ScienceDirect

- Waterproof Reusable Incontinence Pants For Unisex, Soft Sealing Breathable Material, Universal Fit, Bath Shower Cover, Postoperation Hemorrhoids

- Sport equipment and lightbox with hashtag FITNESS AT HOME on floor indoors. Message to promote self-isolation during COVID‑19 pandemic Stock Photo - Alamy

- Sequin Skirt Zita Black // ba&sh

- Daddy's Here (@DaddysHereMovie) / X

- 10:10 The clock secret